with liberty lift, everything is right for you - people, quality, products & service

Real-Time Data For Artificial Lift Optimization

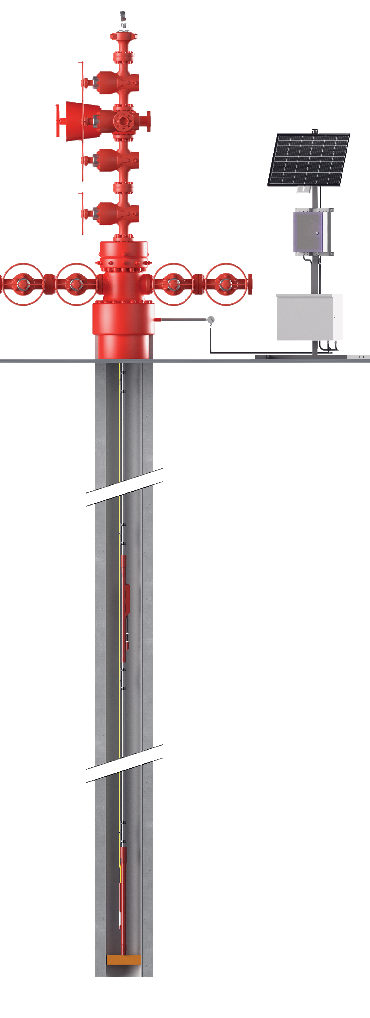

The necessity for Exploration and Production companies to make smart, on the fly decisions has led to an industry seeking data driven solutions, capable of using real time information to optimize production and enhance artificial lift capabilities. Liberty Lift Solutions, recognized for innovative artificial lift technology improvements, has incorporated real-time downhole data acquisition into a simple, yet robust, instrumentation package. The real time data acquisition system provides our customers with accurate bottom-hole temperature and pressure necessary to maximize well productivity. Our real time data acquisition solution is a perfect addition to Liberty Lift’s innovative artificial lift solutions, including the HyRate® gas lift system.

How it works

DOWNHOLE

The Liberty Lift reservoir monitoring system allows data to be collected and transmitted in real-time using an industry leading robust and accurate piezo or quartz gauge. The gauge is deployed on a custom fit carrier and can be ported to read the tubing, annulus, or both. To enhance system reliability, a custom protector program is designed based on the deviation of the wellbore. LLS gauges can accommodate a wide range of wellbore conditions.

The gauge is powered and deployed into the well with TEC (tubing encapsulated cable). Data transmission with the gauge is established and monitored before, during, and after the install. Up to 8 gauges can be deployed on a single TEC cable. The TEC configuration is chosen based on the wellbore environment.

SURFACE

The TEC exits the wellhead using a special wellhead outlet (WHO) with metal to metal sealing to prevent leaks regardless of pressure

Surface Data Acquisition Cards are used to collect, store and transmit the downhole data. The SDA cards are equipped with Modbus outputs which allows data to be sent via SCADA, cell phone or satellite modem using the Cloud to a computer offsite for further interpretation and analysis. If the required 12 V power supply is not available at the wellsite, solar packages with battery backup can be readily supplied.

BENEFITS

- Real-Time BHP and BHT during multi-phase flow regimes

- Reduces operating costs with remote data acquisition

- Simple and rugged spooling installation units

- Compatible with Liberty Lift’s HyRate® annular and tubing gas lift

- Real-time feedback on initial flowback strategies

- Calibrate gas lift design and maximize performance

- Optimize well spacing to efficiently drain the reservoir

- Compatible with Liberty Lift’s smart gas lift controller

COMPONENT FEATURES

GAUGE

- Operates at pressures up to 15,000 psi and temperatures to 150°C (302°F)

- Metal to metal seal for leak prevention and reliability

TUBING ENCAPSULATION CABLE (TEC )

- Available in multiple configurations

- 316L stainless or A825 Inconel armor for corrosion resistance

- Can be designed to suit any wellbore environment

CARRIER/CABLE PROTECTOR

- Optimal protector spacing program to ensure system longevity

- Carrier ported to tubing, annulus, or both

WELLHEAD FEED THROUGH OUTLET (WHO)

- Provides safe exit for TEC from the wellhead

- Combines with junction box to add built-in lightning suppression for ultimate electronics protection

- Metal-to-metal seals prevent leaks

SURFACE DATA ACQUISITION (SDA)

- Versatility in data transmission options

- Surface card options – cost effective single well, or multi well with local memory

- Low power requirements, and solar panel available on request