with liberty lift, everything is right for you - people, quality, products & service

Liberty Lift is your hydraulic lift partner with an innovative solution for oilfield production. Our hydraulic jet pumps for oil wells have many advantages, starting with its cutting edge and simple design. The surface pump, manufactured by industry-recognized Wanner Engineering, is the most expensive part of the unit, but unlike costly downhole ESP pumps, it is placed above ground and easily accessible for any needed repairs with minimal downtime and no need for a workover. The sealless pump design has no packing or stuffing box which can leak or fail prematurely as is often the case with conventional plunger type pumps. The pump can run dry indefinitely even with a blocked suction line. The power fluid is generally condensate, water or hydrocarbon liquids available at the weIl site. Chemicals or diluents can also be combined with the power fluid to address downhole flow and tubular corrosion problems.

Highest Flow Volume in the Industry

The bottom hole assembly of the Liberty Lift system centers around the Select-Jet pump placed in the well. The pump handles high fluid volumes with heavy solids and gas. There are no moving parts in this downhole assembly. Depending on the best solution for unloading the well, the pump incorporates a standard flow option with power fluid injected down the tubing, while taking returns up the casing. Alternatively, the reverse flow jet system allows pumping down the casing annulus with returns up the tubing string. Its flexibility allows it to have slim hole capability with integral joints as small as 1” within a 2 ¼” tubing and 7” casing, offering the highest flow volumes in the industry.

The jet pump system, for sale or rent by Liberty Lift, operates efficiently in multiple applications – shallow or deep wells with vertical, horizontal or multiple deviations. It has low operating costs, no VOC emissions, reduced maintenance and the ability to wireline or hydraulically retrieve downhole parts without workover intervention. It is a reliable and productive choice for wells with wide ranging depths and production capabilities.

Learn more about Liberty Lift’s hydraulic jet surface pump.

Advantages of the Hydraulic Jet Pump Process

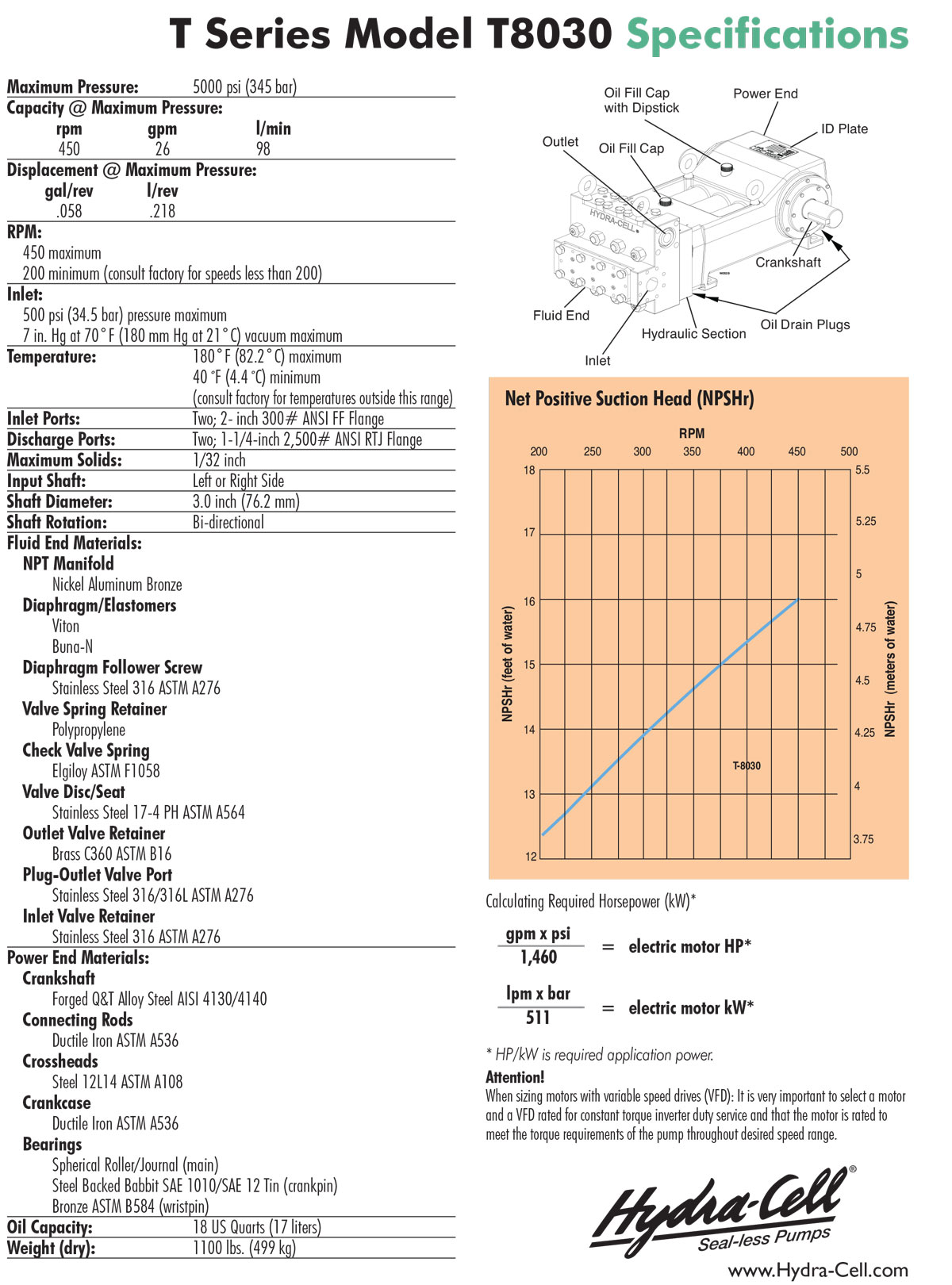

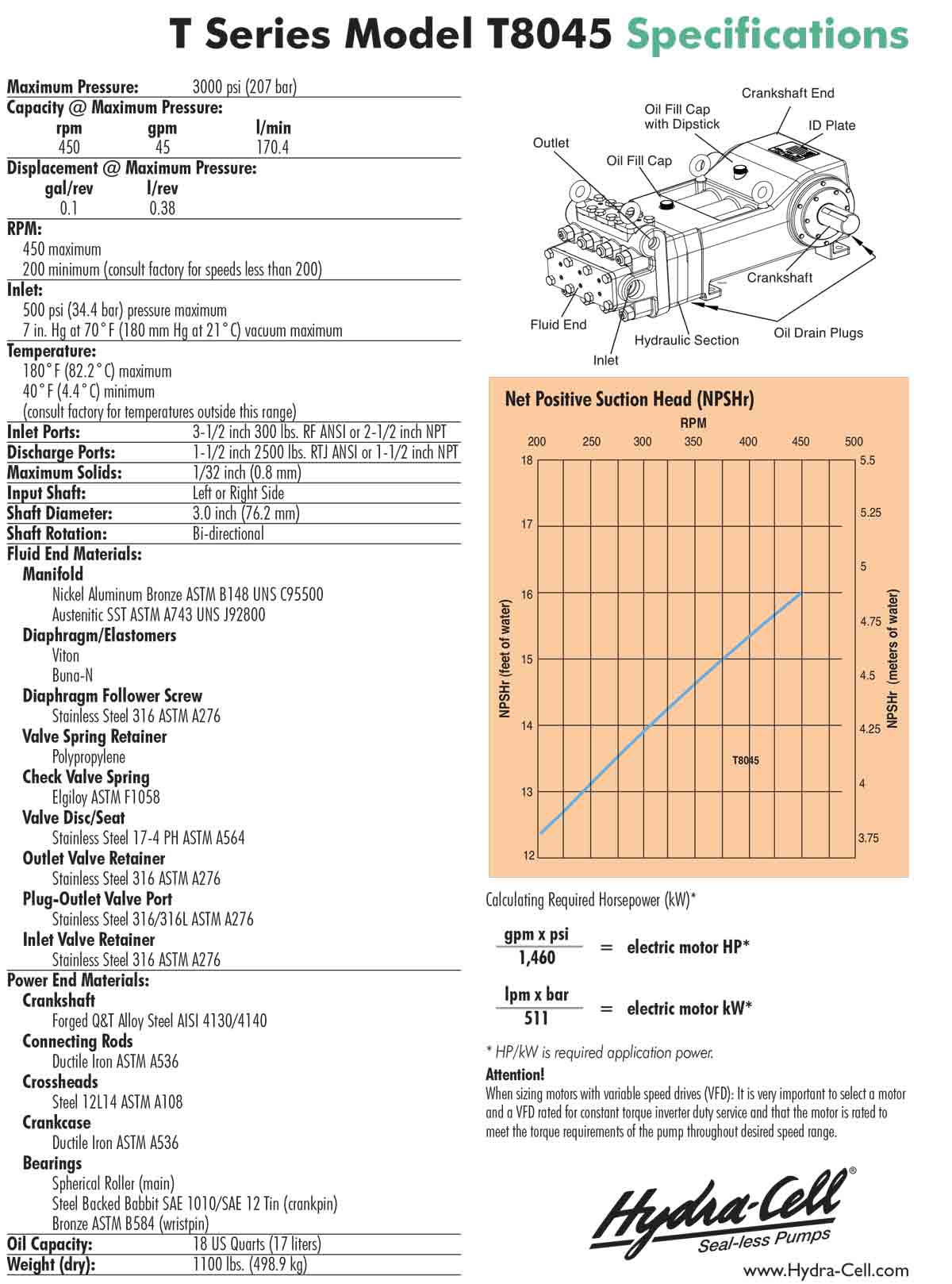

Hydraulic jet pumps are a proven means of artificial lift that have been used for generations in the production of oil and gas. Normally they are utilized for high volume initial production and well unloading with high rates as an alternative to gas lift systems or electric submersible pumps (ESPs). They are also a favorable choice where high flow rates are required in wells having a heavy concentration of sand or other solids from frac operations and can handle high gas volumes. The pumping units are normally skid mounted in a compact above-ground package that includes the hydraulically balanced diaphragm pump that provides power fluid to 5,000 psi pumped down the tubing for returns up the casing or a reverse method of pumping down the casing with tubing returns. The skid includes instrumentation that monitors high and low pressure for both the pumps suction and discharge. In addition, there are meters for flow, high and low oil pressure reading, vibration sensing and pulsation dampening.

Hydraulic jet pump systems have several advantages over the alternative artificial lift methods at this early point in the well’s life cycle. Without an infrastructure that includes wellhead gas availability, the gas lift method is not generally feasible. While ESPs can initially be less expensive as a capital cost item, their reliability in rugged service has been questionable and costly. The major part of their cost is the downhole portion of the unit, positioned at the bottom of the tubing string. When they fail prematurely with mechanical problems, often due to plugging with sand or sediment, they require a workover rig for service and replacement. This operation necessitates pulling the tubing string entirely from the well.

Benefits

- Use of the seal-less diaphragm positive displacement pump reduces downtime and maintenance

- For sale or lease by Liberty Lift

- Economic retrieval without the need for wireline, workover rig, or pulling unit

- Efficiently handles high volumes of returning frac fluids

- Handles solids well

- Can run multiple wells from a single manifold

- Easy on-site nozzle and throat repair

- Chemicals mixed with power fluid can be used to retard corrosion and paraffin

Features

Surface Pump

- Power fluid rates to 3,100 bbls/day

- Injection pressures to 3,000 or 5,000 psi

- Can offer seal-less diaphragm design operates without packing or stuffing box as well along with conventional pump options

- No VOC or environmental exposure

- Can operate indefinitely with blocked or closed suction line without damage

- Compact package design on small, mobile skid

Downhole Jet Pump

- No moving parts downhole

- Proprietary software provides formation monitoring and performance optimization

- Easy retrieval and onsite maintenance

- Versatility for multiple well pad applications

- Handle high volumes of fluids

- Operates efficiently in vertical, deviated and horizontal wells

- Can be wireline or hydraulically retrieved

- Can take returns up the casing (conventional) or up the tubing (reverse flow)

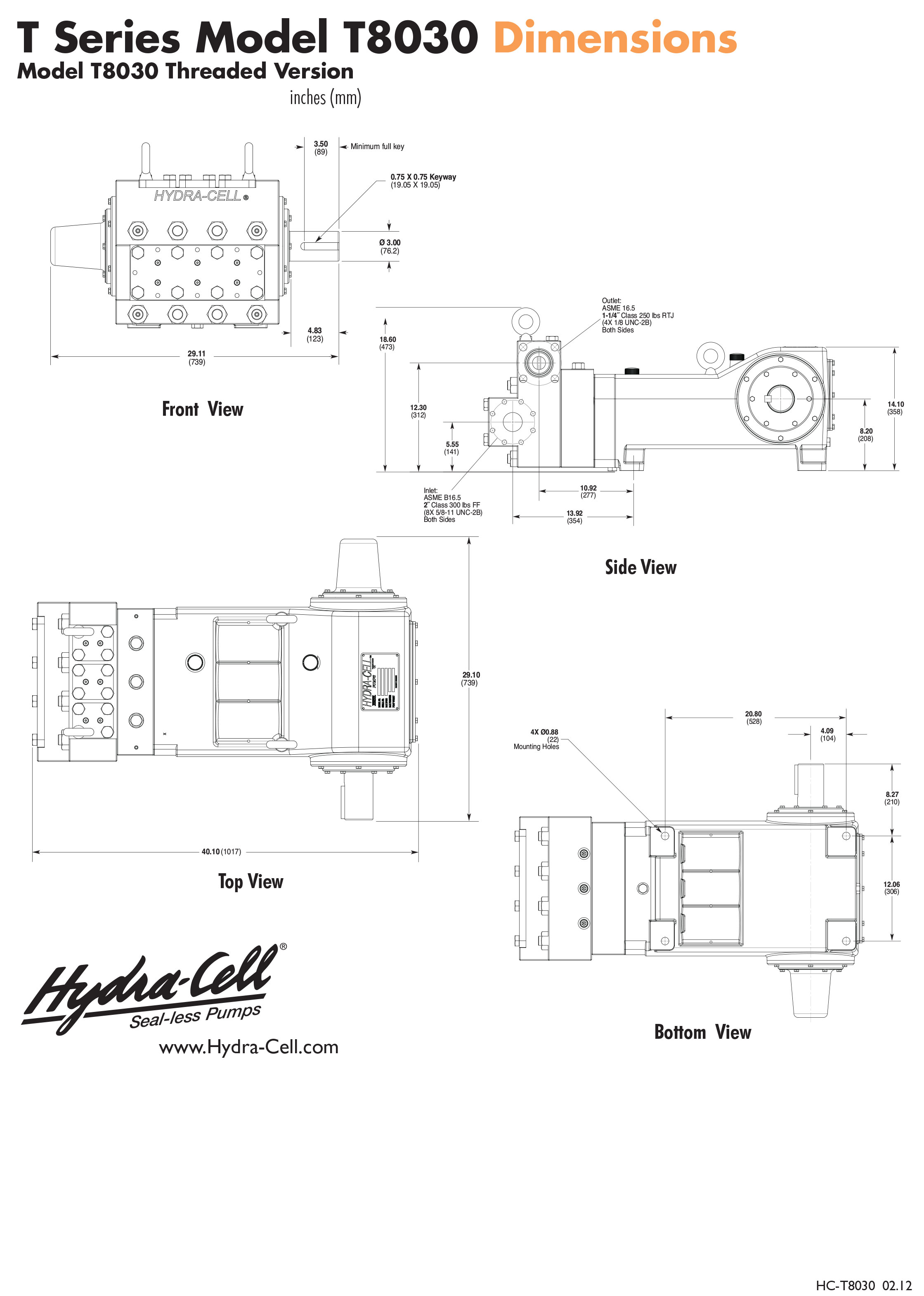

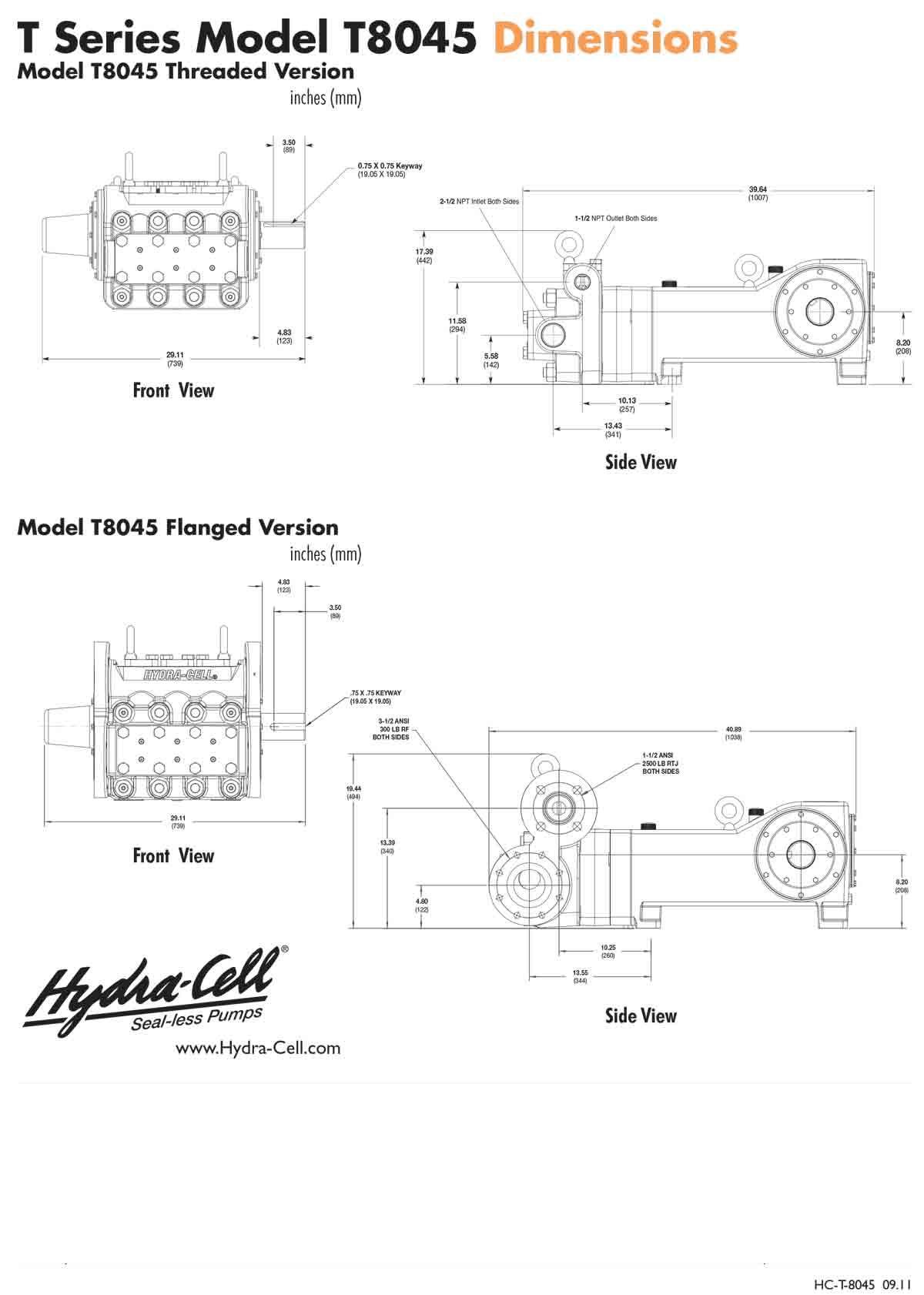

Technical Specifications

Please click on the tabs below to view the technical specifications for that Liberty Lift product.

Call us at 713-575-2300 or email us at sales@libertylift.com Liberty Lift has locations in the major producing regions of the United States.